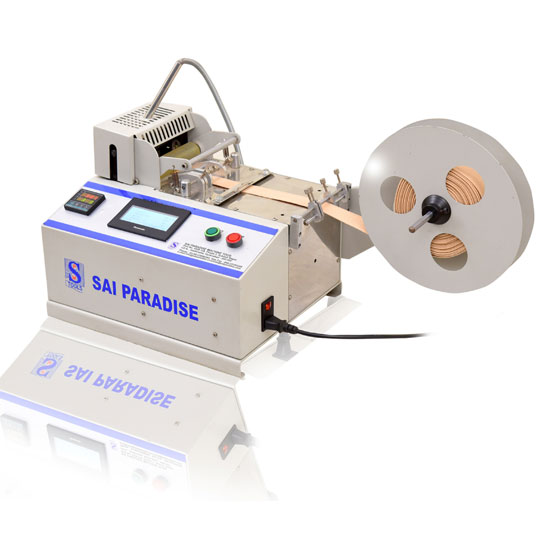

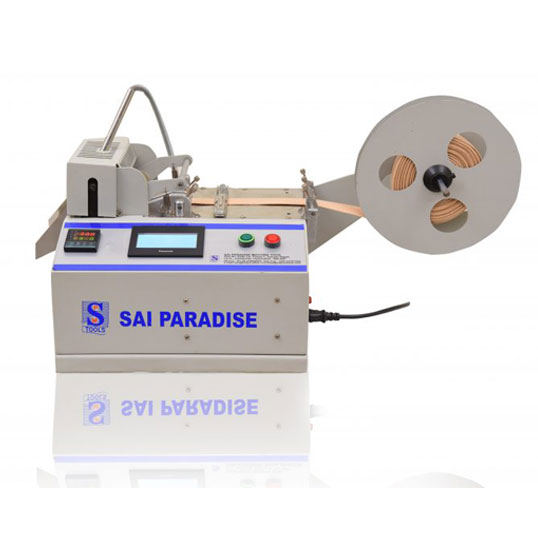

Description

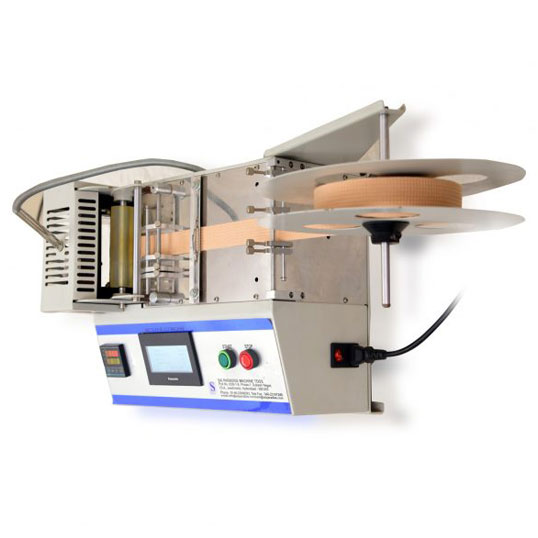

The set up and operation of SL-100H is managed through the use of electronic counters, the PLC based controls and touch screen (HMI) with servo motors. Material guides are easily adjusted for different applications requirements.

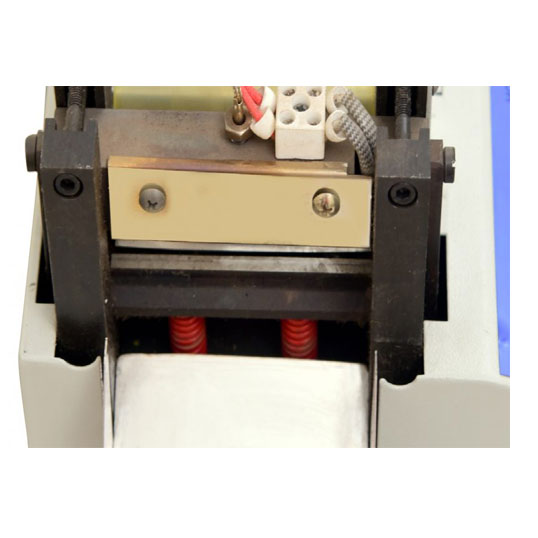

Multi materials guides are also available to feed more than one material source for more productivity. Additional design features includes a durable roller feed system and strong cutting mechanism designed for long life and continuous operations.